- By falm

- June 4, 2020

- Buying Pallets

The Ultimate Guide To Buying Pallets

Click here to download a version of this guide.

Why Use Pallets?

Pallets have been used for over a century both in the U.S. and all around the world. Pallets are used to store and transport both commercial and industrial products. Aside from being incredibly functional, pallets can bring a diverse range of benefits to your business.

For example, pallets allow you to move large quantities of product at a fast rate. The shape and loading capacity of pallets also assists workers in quickly loading and unloading trucks. Moreover, pallets are easy to tore and stack, which helps to free up space in your dock and warehouse.

Best of all, pallets reduce the need for manual handling. This can lead to less product damage — and even fewer worker injuries.

Though the trend of palletizing is on the rise, it can be a bit daunting to “jump in” to the pallet industry. Don’t worry — in this guide, we’ll review everything you need to know before buying pallets, including which materials, pallet designs, and grades make for the best pallets to buy to meet your company’s needs. This manual will help you learn why purchasing used pallets is better than buying new ones.

Pallet Specifications

New vs. Used Pallets

When determining which pallets are the best pallets to buy, you’ll first need to choose between new or used pallets. New pallets are constructed from scratch with fresh lumber. Used pallets, on the other hand, can be constructed in a few different ways:

- Recycled/Repaired Pallets – pallets that previously had damaged boards that have been replaced by new or used boards.

- Remanufactured Pallets – pallets that are built by reusing board components (used lumber) to build a new pallet configuration.

- Combo Pallets – pallets that are a combination of used and recycled pallets, with some deck boards made of new lumber.

Used pallets are a great option, as they are environmentally friendly and help reduce your company’s carbon footprint. Price is another factor to consider when choosing between new and used pallets. In general, a pallet’s purchasing price could raise, so having the option to buy used instead of new pallets can save you money and stress. Used pallets will always be cheaper than new pallets of a similar design; however, the prices of each particular type of used pallet will vary depending on the specifics of the pallets.

Pallet Sizes

Pallets can be built in any custom size, but there is also a list of standard sizes that suit the needs of most buyers. A standard pallet can hold approximately 4,600 pounds. The most common dimensions are:

- 48″×40″ (this is the most common size)

- 42″×42″

- 48″×48″

Though standard-size pallets are most popular, you might run into occasions that call for custom dimensions. For example, if you have oddly-sized/shaped products that need to be shipped, it’s a good idea to consider a custom pallet over a standard pallet. Buying customized pallets can save time and energy when attempting to fit everything into the pallets at once.

Custom pallets can be built as large as you can imagine! In fact, we currently build a 26-foot pallet for one of our customers. To put this in perspective, the most common pallet size is roughly 4 feet by 3.5 feet — this custom order is huge in comparison!

Keep in mind, though, that the larger your pallet, the longer the turnaround time may be due to finding suitable lumber. While buying pallets, whether customized or not, work with your supplier to get material that’s available and ready to use.

Additionally, the larger the pallet, the higher the cost due to increased materials (lumber, nails, and screws), and less pallets per truck for higher-per-pallet transportation costs.

Whether standard or custom, obtaining the best pallets to buy for your job can mitigate product damage, reduce worksite injuries, and optimize your company’s automation lines. Pallets also allow manufacturers to maximize unit load capacities, reduce the number of truck deliveries, and even reduce transportation costs.

If you’re unsure whether you need a standard or custom pallet, contact us either via our website or the number listed below – we’d be happy to help you identify which pallets best meet your needs before purchasing pallets. It is hard to find the right pallets, but with our help, we can point you in the right direction.

Pallet Size vs. Truck Size

We’ve already mentioned a ton of different pallet measurements, so now you’re probably wondering how pallet size compares to the size of an average truck bed.

Most trucks are 96 inches wide, which means that two standard 48-inch pallets can fit side by side. A 53-foot (length) truck can typically carry 26 single-stacked 48×40 pallets, and a 48-foot truck can carry 24 single-stacked 48×40 pallets. See what we mean when we say that pallets can help you maximize unit load capacities?

Hardwood vs. Softwood Pallets

Most pallet suppliers will offer a variety of wood species for pallet construction. These species are divided into hardwood and softwood varieties. Hardwood is more dense, so it tends to create stronger pallets. But, softwood pallets can mimic hardwood strength by increasing the thickness of the boards.

At FALM, we use a pallet design software that considers both the density of the lumber and your company’s load size, and we determine which type of wood/density of wood is needed to safely carry your intended load.

2-Way vs. 4-Way Pallets

The main difference between 2-way and 4-way pallets has to do with accessibility and forklift entry. You see, 2-way pallets have forklift openings on only two opposite sides of the pallet. 2-way pallets are also called “un-notched” pallets.

By contrast, 4-way pallets have forklift openings on all four sides of the pallet, allowing a forklift to lock in and lift the pallet when approaching from any direction. Stringer vs. Block Pallets “Stringer” and “block” refer to two different method of pallet assembly. Stringer and block pallets are both able to handle heavy loads, so when selecting a design, you should mainly focus on how you plan to transport your pallets.

- Stringer pallets: These pallets are 2-way in their forklift openings, and they rely on stringer boards to support the load. Stringer pallets can also have notches in the side to create a partial four-way forklift entry.

- Block Pallets: These pallets are generally considered to be more durable than stringers. Block pallets feature a 4-way forklift entry, and they use blocks of solid wood to support the load. However, block pallets re usually more expensive than stringer models because they are more difficult to assemble and require more lumber.

Pallet Grades

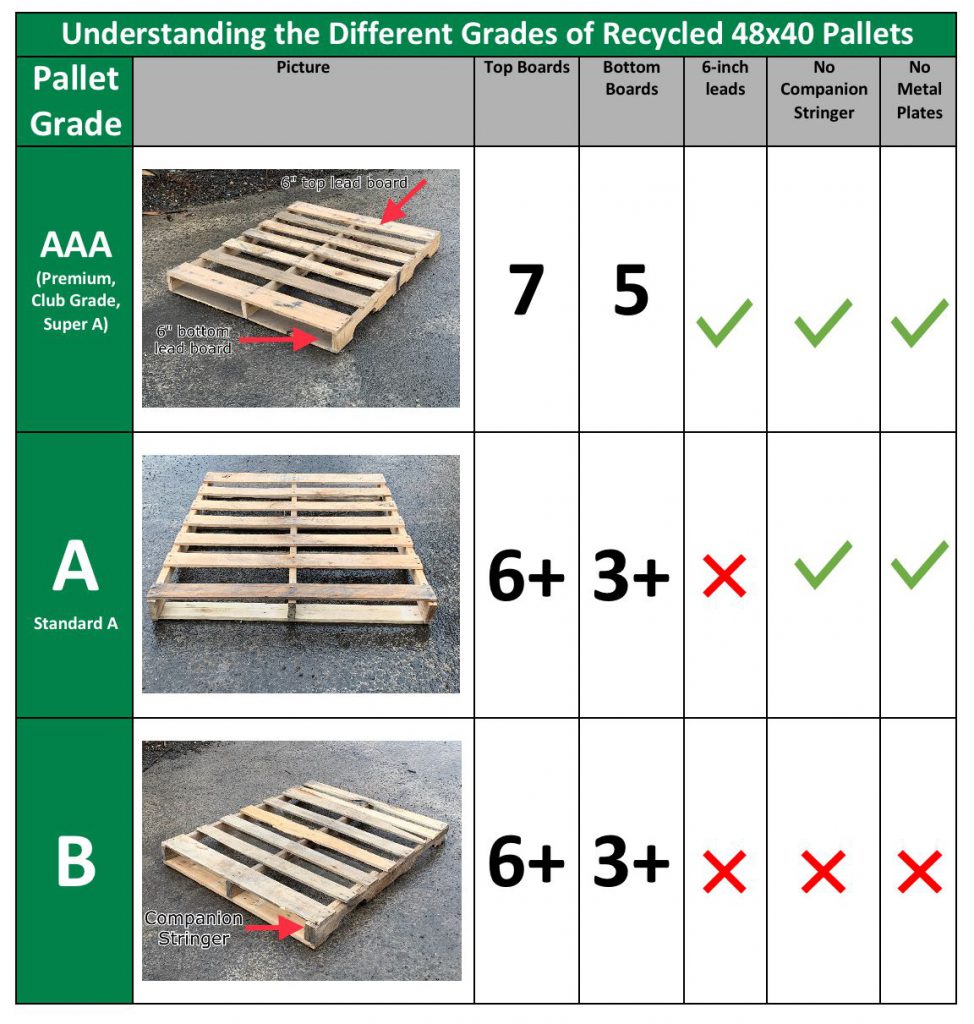

The pallet industry has established a grading system to assess the condition of recycled pallets. At FALM, we rarely quote for pallets beyond Grade A and Grade B, as lower pallet grades are less structurally sound. So, for the purposes of this guide, we will only look at the definitions and qualifications of Grades A & B.

- Grade A (also referred to as #1)“Grade A” pallets are recycled pallets that have been refurbished to near original condition. All damaged boards have been replaced, and this pallet is highly dependable. You might mistake Grade A pallets for new pallets!The specs on an A-Grade pallet are more consistent than a B, and A-Grades are likely to have experienced fewer shipment cycles than Bs.Also, Grade A pallets will never have block repairs to stringers, but each stringer can have up to one repair plate to strengthen a splint.

- Grade B (also referred to as #2)“Grade B” pallets have been previously used and typically have experienced damage to at least one stringer. To fix, or reinforce, the damaged wood, an additional runner is typically placed alongside the broken or cracked piece. The top and bottom deck boards may have also been replaced in previous repair cycles, which means the deck configuration on “B” pallets may not be consistent, but they are still a reliable alternative to new pallets.Grade B pallets have repairs on their stringers, and they can have plates or staples on cracked boards. Additionally, Grade B pallets can have chips or partial split boards.

The chart on the following page can also assist you in identifying different pallet grades:

Pallet Materials

There are a few different types of pallet materials to choose from, including wood, compressed wood, metal, cardboard, and plastic. Wood is obviously the most common material for pallets, but there are unique advantages to each type.

FALM only handles wood and compressed wood pallets, and the wooden pallets are ready to sell.

These kinds of pallets are the easiest to repair and recycle, so they are both incredibly eco-friendly and affordable.

Pallet Treatment

Why are pallets treated?

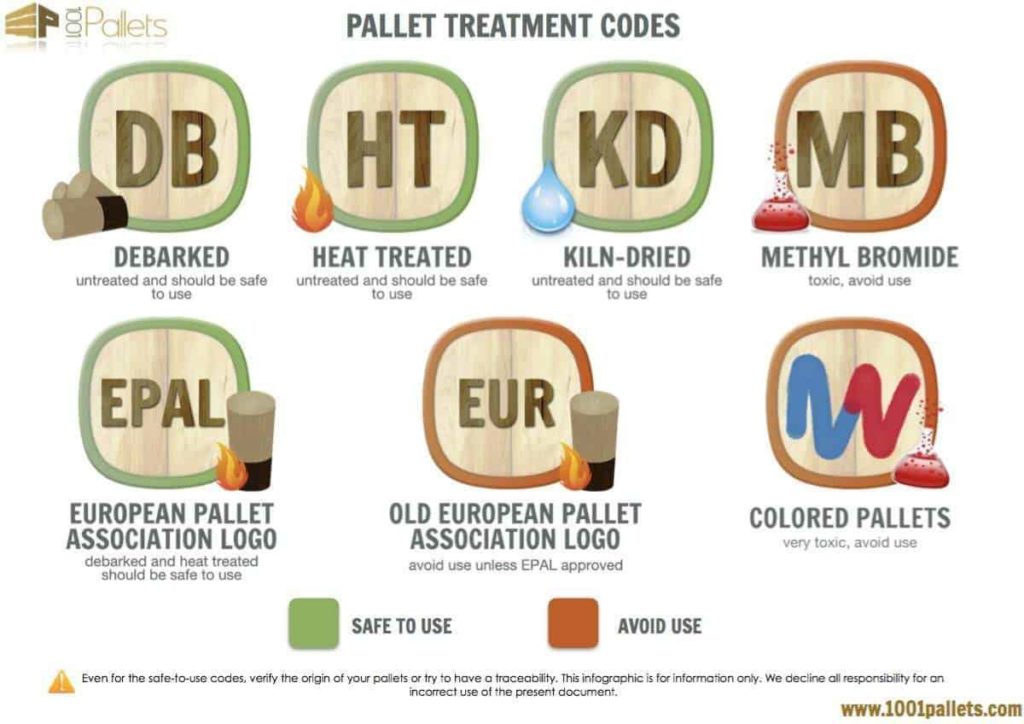

If a pallet is going to be used for an international shipment, then it must be a treated pallet that meets ISPM-15 (International Phytosanitary Measure) standards. The ISPM states that wood used for international shipping must be treated to prevent the spread of disease and insect infestation between countries. Below, we’ve identified the most common types of pallet treatment:

- Heat Treated Pallets: The process of heat treatment for pallets is mandated by the U.S. customs authorities. It is the most common way to meet ISPM-15 standards. When pallets are constructed with green lumber, insects frequently try to seek refuge in the freshly-cut wood. When pallets are treated with extreme heat, these bugs either flee or are killed — and this reduces the risk of spreading insect infestations between countries. Heat-treated pallets’ costs vary, but they typically cost between $0.75 to $1.25 per pallet.

- Methyl Bromide (MB) Treated Pallets: In this treatment method, pallets are stacked in a sealed chamber and sprayed with the pesticide, methyl bromide. The chemical soaks into the wood and dries, which kills insects and prevents the growth of mold.

Wood pallets manufactured in the US, Canada and Europe are no longer treated with MB, due to numerous health hazards posed by the chemical. *It’s still possible to find pallets that have been MB treated, but because of their high toxicity, we don’t recommend using these pallets.* - Kiln-Dried Pallets: New wood pallets are often made from recently harvested trees. Before this lumber can be constructed into a pallet, it needs to be thoroughly dried. To accomplish this, the fresh lumber (green lumber) can either be left outside to dry (air-dried) or placed into a kiln to dry (kiln-dried).

Kiln-drying is advantageous because it quickly eliminates moisture in the wood — the speed of this process prevents warping and it reduces weight. Be aware that while kilndrying is a great treatment for green lumber, it does not meet ISPM-15 standards. Kiln-treated wood must still undergo heat treatment if it will be used for international shipping.

How do I know if my pallets have been treated?

Once a pallet has been treated, a certification label (shown below) will be stamped onto the side of the pallet. If the pallet has been repaired with untreated wood, then the entire pallet needs to be retreated and re-stamped.

You can learn a lot by looking at a pallet treatment stamp, including the country of origin and treatment method used.

For instance, the “US” in the above stamp stands for “United States,” and the “HT” stands for “Heat Treatment.”

Here is a useful chart of pallet treatment codes:

Renting vs. Buying

Renting Pallets

Renting pallets has become more common in recent years. Large pallet pool companies like CHEP (blue pallets) and PECO (red pallets) have a notable presence in the U.S.

While renting typically has lower upfront costs, it does come with a few disadvantages as well.

For example, rented pallets must be returned to the vendor once your shipment is completed. This leaves you with few pallets on hand for unforeseen shipments or last-minute customer orders. In this way, renting pallets can cause you to miss out on business.

And, while renting may seem cheaper due to the advertised rate, rented pallets typically come with a number of surprising fees. In fact, the typical pallet rental contract includes:

- Issue Fee

- Transfer Fee

- Non-Participant Fee (not all rental companies charge this)

- Heat-Treating Fee

- Lost Pallet Fee

Most of these fees are minimal, but some — such as the transfer fee and the non-participant fee (occurs when you ship to a company outside of the rental company’s network) — can quickly catapult you over budget.

Buying Pallets

On the other hand, the costs associated with buying pallets are more straightforward. Yes, there is a higher initial cost, but there are fewer hidden fees.

Plus, once you purchase your pallets, they are 100% yours – you can use them, reuse them, or recycle them. Even better — you’ll always have an in-house means of transporting goods and fulfilling orders. Purchasing pallets is a great investment for the longevity of your business.

If you have a constant need for pallets, you can even create your own recovery system. Creating a closed pallet recycling loop comes with many benefits. FALM is an expert in creating pallet recycling and recovery systems, so if you have any questions about how this may benefit your company, please feel free to contact us at the number listed at the bottom of the page.

Where to Buy Pallets

Are you still unsure regarding how to buy pallets for your business?

How do you get pallets? Read on to find out how you can obtain pallets for your business. First off, when you are ready to buy your pallets, new or used, you can look in a couple different places. There’s always the chance to buy in bulk from different pallet manufacturers across the country. Or, you can choose to work with a pallet management company, like First Alliance Logistics Management (FALM), who has partners across the country that can help you find pallets wherever and whenever the need arises.

Because of freight costs, you should look for a pallet company located within 50-100 miles of your facility. Using a pallet provider with a nationwide scope can be incredibly valuable, because it allows you to consolidate vendors and maintain only one point of contact for your entire pallet sourcing needs.

Pallet Pricing

As we mentioned before, there are a lot of variables when it comes to the price of pallets, which makes it difficult to provide a standard pricing list. But, we can give you a list of questions that a pallet manufacturer will ask in order to determine a quote:

- What is your typical pallet monthly volume and ordering frequency?

- What material should be used to build the pallet?

- Do you prefer new or used pallets?

- Do you need a custom or standard pallet size?

- What are the dimensions needed for your pallet?

- Where are you located?

- Do you need treated/untreated pallets?

All of the above factors play a role in pricing your pallets. We prioritize quality and safety in every wooden pallet we provide. Our rigorous quality control process ensures each pallet is free from defects and common hazards. We use durable, high-quality wood that’s designed for longevity and reliable performance. By buying pallets from our team, you’re investing in not just a product but also in the peace of mind that comes with knowing you’ve made a safe, responsible choice.

If you’re interested in a quote, contact us with your desired specs today. We’ll link you up with a supplier who can meet your exact needs.

We hope that this guide has helped you better understand the process and decisions involved in buying pallets. If you have any more questions, check out our FAQ page or contact us directly.

We’ll be happy to help you find the perfect pallets for your business!