The pulsing heart of modern commerce, the logistics industry, is undergoing a revolution powered by robotics. This transformation is more than just a technological upgrade; it’s a domino effect, reshaping the very nature of supply chains. The digital and physical are fusing in new, innovative ways, from the cavernous holdings of e-commerce giants to the intricacies of local distribution centers.

Understanding and harnessing the potential of robotics is imperative for logistics professionals navigating this shift. Therefore, we’re here to explain how robotics are affecting the logistics industry so you’re ready for what comes next.

The Rise of Robotics in Logistics

The already bustling logistics industry has propelled itself into overdrive with the rise of e-commerce. Rapid order fulfillment and seamless tracking have become the new norms, necessitating a level of speed and accuracy that human labor alone can no longer guarantee. Enter robotics: these intelligent, automated systems are no longer just tools for efficiency but are becoming fundamental to the survival and success of logistics operations.

The Anatomy of a Robot in Logistics

Robotic systems in logistics come in various forms, each designed to fulfill specific tasks. Their integration into the supply chain is multi-faceted, from autonomous mobile robots (AMRs) and automated guided vehicles (AGVs) that transport pallets of goods within warehouses to robotic arms that handle picking and packing.

How Robots Navigate the Warehouse

Warehouses are complex environments ripe with challenges—from constantly shifting inventory to the need for continuous workflow optimization. Today’s robots utilize an array of advanced technologies, including LIDAR (Light Detection and Ranging) sensors, computer vision, and artificial intelligence, to navigate and perform tasks with astonishing precision.

Benefits of Robotics for the Logistics Sector

The adoption of robotics is yielding a plethora of advantages for an industry that operates on razor-thin margins and stringent schedules. Here are some of the main benefits a company might be able to take advantage of for its operations.

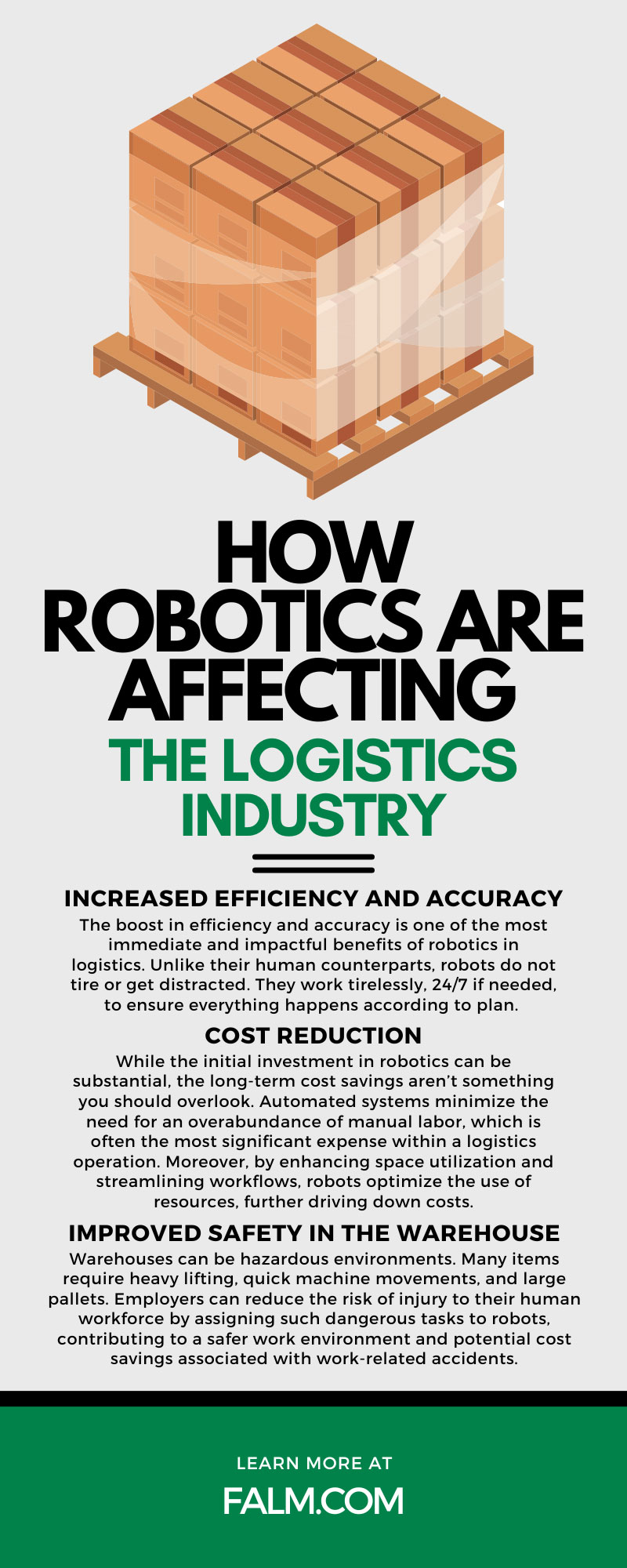

Increased Efficiency and Accuracy

The boost in efficiency and accuracy is one of the most immediate and impactful benefits of robotics in logistics. Unlike their human counterparts, robots do not tire or get distracted. They work tirelessly, 24/7 if needed, to ensure everything happens according to plan. This increased efficiency significantly reduces the incidence of errors that can be costly in terms of both time and resources.

Cost Reduction

While the initial investment in robotics can be substantial, the long-term cost savings aren’t something you should overlook. Automated systems minimize the need for an overabundance of manual labor, which is often the most significant expense within a logistics operation. Moreover, by enhancing space utilization and streamlining workflows, robots optimize the use of resources, further driving down costs.

Improved Safety in the Warehouse

Warehouses can be hazardous environments. Many items require heavy lifting, quick machine movements, and large pallets. Employers can reduce the risk of injury to their human workforce by assigning such dangerous tasks to robots, contributing to a safer work environment and potential cost savings associated with work-related accidents.

Enhanced Tracking and Traceability

Robots are meticulous documentarians, capable of logging every movement and transaction within a warehouse. This exactness ensures greater accountability and enables traceability, which is invaluable when troubleshooting and adhering to compliance regulations.

Overcoming the Challenges of Implementing Robotics in Logistics

Despite all the advantages, the road to robotic integration in logistics is not without its hurdles. It’s a journey that demands strategic planning and the navigation of numerous considerations. Here are some notable challenges your company should address.

Navigating the Upfront Costs

As previously stated, the initial investment required is one of the most significant barriers to entry for logistics companies looking to adopt robotics. While the ROI substantiates the costs, many businesses, especially small and medium-sized enterprises, struggle to justify the upfront price tags. The “sticker price” will hold back many businesses early on, but as time passes, these initial costs should become more manageable.

Workforce Adaptation and Training

Companies must strategize on how to re-skill employees for new roles and alleviate any concerns around job security brought about by automation. With careful planning, you can set up a roadmap that should alleviate these issues.

Maintenance and Technical Support

It’s no secret that robotic systems are highly technical and require regular maintenance to function optimally. Logistics companies must invest in the necessary support infrastructure and training to manage and service these sophisticated machines effectively if they want to find continued success.

Future Trends and Innovations in Robotics for Logistics

While our current advancements are quite impressive, robotics are affecting the logistics industry in ways that point to a future where automation will be even more pervasive. You should look into the future potential of such machinery before diving into the world of robotics yourself.

Predictions for Robotic Adoption

Analysts predict a steep rise in the adoption of robotics in logistics over the next decade. The future holds a promise of even more intelligent and adaptive systems capable of working in concert with humans to increase operational efficiency and innovate new logistics paradigms.

Emerging Technologies

Beyond the robots we currently know, emerging technologies like drones for inventory tracking and exoskeletons to enhance worker capabilities are on the cusp of deployment. These advancements will redefine the logistical landscape, making it leaner, greener, and more capable than ever before.

The Human Element

Despite the encroachment of automation, the role of the human worker will remain critical. Machines are adept at repetitive tasks, but human creativity and problem-solving abilities continue to be indispensable, especially in the face of the unexpected and the need for strategic oversight. Be sure not to forget this as you make changes throughout your business’s transition.

Embracing Robotics as a Competitive Edge

The message is clear for logistics professionals: Robots are no longer the harbingers of a distant future but are the driving force of the present. Those who harness this technology stand to gain a significant competitive edge, leading the way in efficiency, sustainability, and innovation. You must embrace these changes to remain competitive.

Crafting a Robotic Strategy

Companies must craft a comprehensive strategy that aligns technology adoption with business objectives to reap the benefits of robotics. This strategy should include careful evaluation of existing workflows, potential ROI analysis, and a long-term vision for the role of robotics in the supply chain. Without a plan, you’ll likely run out of money before even getting started.

Preparing the Workforce for Change

Once your strategy is in place, you’ll need to prepare the workforce for the arrival of robotic systems. Ongoing education and professional development will be essential in ensuring that employees have the skills necessary to thrive in the new logistic paradigm.

Don’t Forget the Non-Robotic Components

Even though the focus of the future of logistics is on robotics, you can’t forget all of the smaller components that make these systems possible. You’ll need to keep these components, from storage systems to pallets, up-to-date to ensure compatibility with your robotic systems. Fortunately, FALM is your go-to pallet vendor in this scenario. We make an effort to keep our products updated, ensuring our offerings and services meet the ever-changing industry standards and our clients’ needs. Contact us today to learn more about how we can help your logistics business thrive!