Warehouse dock management is a critical aspect of the supply chain; it plays a role in the efficiency and success of business and freight logistics. Dock management also maintains the smooth flow of goods in and out of a warehouse while minimizing delays, reducing errors, and improving worker productivity.

Let’s explore the fundamentals of what warehouse dock management is and some tips to improve it. We’ll help your business form a logistics operation that runs like a well-oiled machine!

Understanding Warehouse Dock Management

Warehouse dock management involves coordinating all activities related to loading and unloading goods at the dock area: scheduling, staffing, equipment management, and safety protocols. Effective dock management reduces bottlenecks, improves turnaround times, and contributes to warehouse efficiency.

The Importance of Efficient Dock Management

Efficient dock management is essential for several reasons. First, it allows teams to load and unload trucks promptly and reduces wait times for drivers.

Second, it minimizes the risk of errors, such as shipping the wrong products or damaging goods during handling. Third, effective dock management enhances safety by encouraging workers to follow established workplace procedures.

Key Elements of Warehouse Dock Management

Several key elements contribute to effective warehouse dock management:

- Scheduling for trucks and personnel avoids congestion and provides smooth operations.

- Having the right number of trained staff at the dock makes it easier to handle the volume of goods.

- Keep all equipment, such as forklifts and pallet jacks, in good working condition and readily available.

- Implementing and enforcing safety protocols protects workers and prevents accidents.

Tips for Improving Warehouse Dock Management

Improving warehouse dock management requires a combination of strategic planning, technology integration, and continuous improvement. Below are some actionable tips to enhance your dock management processes.

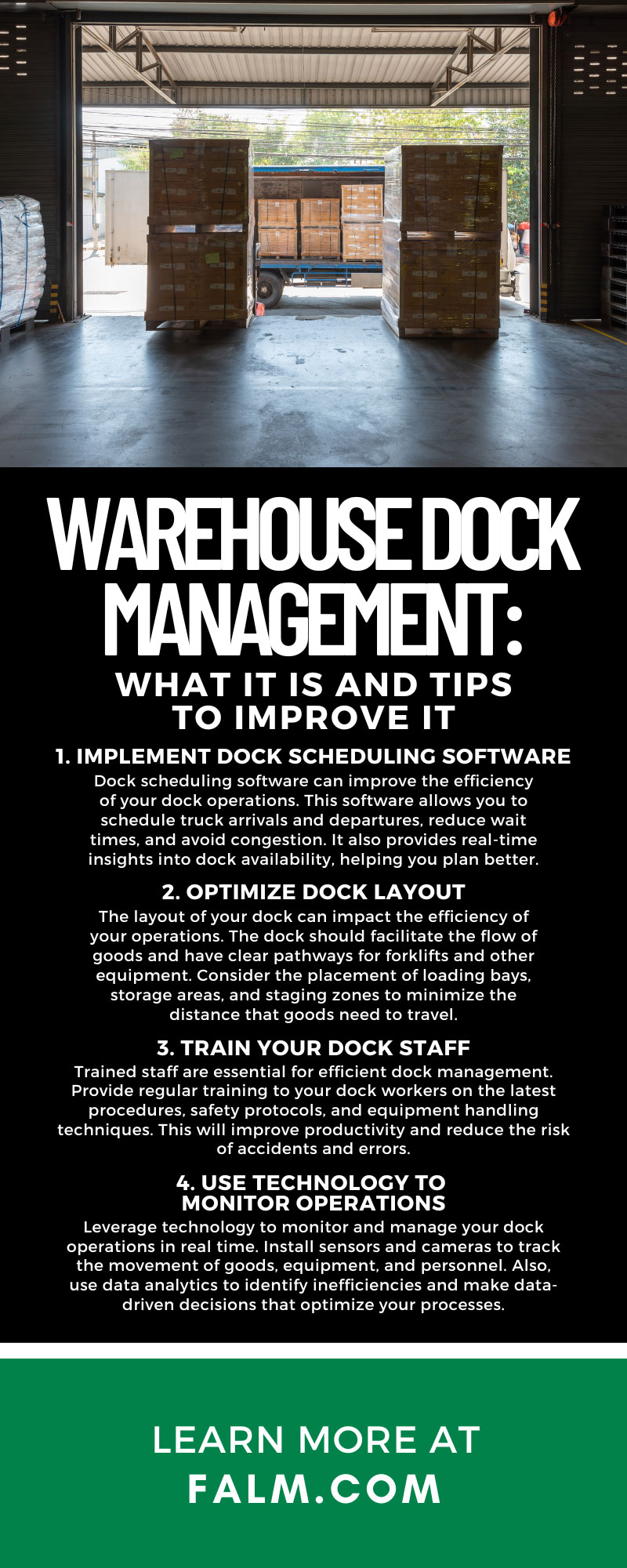

1. Implement Dock Scheduling Software

Dock scheduling software can improve the efficiency of your dock operations. This software allows you to schedule truck arrivals and departures, reduce wait times, and avoid congestion. It also provides real-time insights into dock availability, helping you plan better.

2. Optimize Dock Layout

The layout of your dock can impact the efficiency of your operations. The dock should facilitate the flow of goods and have clear pathways for forklifts and other equipment. Consider the placement of loading bays, storage areas, and staging zones to minimize the distance that goods need to travel.

3. Train Your Dock Staff

Trained staff are essential for efficient dock management. Provide regular training to your dock workers on the latest procedures, safety protocols, and equipment handling techniques. This will improve productivity and reduce the risk of accidents and errors.

4. Use Technology To Monitor Operations

Leverage technology to monitor and manage your dock operations in real time. Install sensors and cameras to track the movement of goods, equipment, and personnel. Also, use data analytics to identify inefficiencies and make data-driven decisions that optimize your processes.

5. Streamline Communication

Effective communication is the key to successful dock management. You must keep your dock staff, drivers, and warehouse personnel on the same page. Use communication tools such as radios or messaging apps to facilitate instant communication and reduce misunderstandings and delays.

6. Use Load Planning Tools

Load planning tools can help you optimize loading and unloading processes in a truck or container to maximize space utilization and minimize the risk of damage during transit. Load planning also reduces the time needed to load and unload goods, improving overall efficiency.

7. Conduct Regular Maintenance on Equipment

Regular maintenance of dock equipment is essential to prevent breakdowns and maintain smooth operations. Schedule routine inspections and servicing of forklifts, pallet jacks, and other equipment. Address issues promptly to avoid disruptions and protect your dock workers from malfunctioning equipment.

8. Monitor Key Performance Indicators

Monitoring key performance indicators (KPIs) is crucial for assessing the efficiency of your dock management processes. Track metrics such as dock utilization, turnaround times, and error rates. Use this data to identify areas for improvement, and implement changes to enhance your dock operations.

9. Continuously Improve Your Processes

Continuous improvement is the key to long-term success in warehouse dock management. Regularly review your processes, gather feedback from staff, and stay updated on the latest industry trends and technologies.

Implement changes incrementally, and monitor their impact to optimize your dock operations. These changes might include adopting an efficient used pallets pickup strategy. By having a third party retrieve your pallets, you can maintain organization and improve throughput.

The Role of Technology in Dock Management

From dock scheduling software to real-time monitoring tools, technology streamlines operations and improves efficiency. Embracing automation and digital tools can enhance your dock management processes, reduce manual errors, and increase worker productivity.

Dock Scheduling and Optimization Software

One impactful technological advancement in dock management is the use of dock scheduling and optimization software. This software allows managers to coordinate the arrival and departure of trucks with loading bay teams.

Advanced algorithms can predict delays, reschedule appointments, and optimize routes based on live traffic data. This technology minimizes idle time for trucks, reduces bottlenecks, and allows goods to move in and out of the warehouse seamlessly.

Furthermore, dock scheduling software can integrate with warehouse management systems (WMS) to provide a holistic view of the supply chain. This integration allows for better resource planning and helps your company avoid the common pitfalls of overbooking or underutilization.

Real-Time Monitoring and Analytics

Real-time monitoring tools can also transform dock management. These tools utilize sensors, cameras, and GPS tracking to provide live data on the status of dock operations.

Managers can monitor the movement of goods, the availability of loading bays, and the performance of dock workers from a centralized dashboard. Visibility enables quicker decision-making and allows managers to address issues as they arise.

The Power of Automation in Dock Management

Automation is another key aspect of modern dock management. These systems can handle repetitive tasks, such as loading and unloading, with greater speed and accuracy than workers.

Automation also extends to inventory management, where workers can use RFID tags and barcode scanners to track goods and used pallets pickup in real time. This tracking tech reduces the risk of errors associated with manual data entry and helps your company maintain accurate inventory levels.

Optimizing Warehouse Dock Management for Success

Warehouse dock management is a critical component of business and freight logistics. It’s important to understand what it is and the tips to improve your dock operations and enhance safety.

Additionally, consider the importance of used pallets pickup as part of your dock management strategy. Contact First Alliance Logistics Management today to learn how we can help with your pallet removal needs. Visit our website for more information about these services.