- By First Alliance Logistics Management

- December 19, 2024

- Buying Pallets

Wooden pallets are vital in supply chain management, providing a sturdy foundation for storing and transporting goods. However, not all of them share the same qualities and must undergo different treatment processes.

The types of treatments used on wooden pallets can affect their performance, durability, and regulatory compliance. Let’s explore the various treatments available for wooden pallets, helping business owners and logistics managers make informed decisions when choosing wood pallets for their operations.

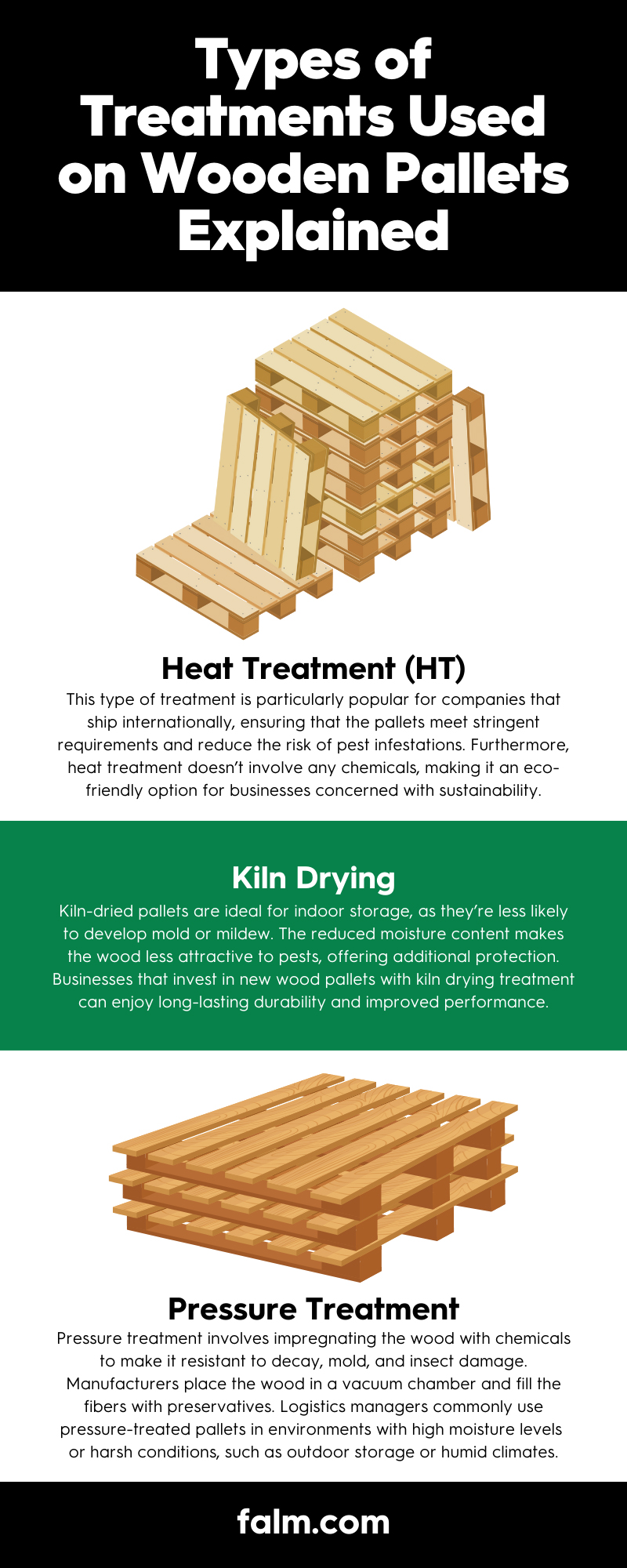

Heat Treatment (HT)

Heat treatment is a common method many professionals use to protect wooden pallets from pests. It involves exposing the wood to high temperatures, typically around 56°C (132.8°F) for at least 30 minutes.

This process effectively eliminates any harmful insects or larvae hiding in the wood. Heat-treated pallets comply with international regulations, such as ISPM 15, which govern the safe movement of wood packaging materials across borders.

This type of treatment is particularly popular for companies that ship internationally, ensuring that the pallets meet stringent requirements and reduce the risk of pest infestations. Furthermore, heat treatment doesn’t involve any chemicals, making it an eco-friendly option for businesses concerned with sustainability.

Kiln Drying

Many who are new to treating wood confuse kiln drying with heat treatment, but it serves a different purpose. While heat treatment focuses on pest control, kiln drying aims to reduce the moisture content in the wood.

By drying the wood in a kiln, the pallets become lighter, stronger, and less prone to warping or cracking. This treatment is especially important for businesses dealing with heavy loads or moisture-sensitive products.

Kiln-dried pallets are ideal for indoor storage, as they’re less likely to develop mold or mildew. The reduced moisture content makes the wood less attractive to pests, offering additional protection. Businesses that invest in new wood pallets with kiln drying treatment can enjoy long-lasting durability and improved performance.

Pressure Treatment

Pressure treatment involves impregnating the wood with chemicals to make it resistant to decay, mold, and insect damage. Manufacturers place the wood in a vacuum chamber and fill the fibers with preservatives. Logistics managers commonly use pressure-treated pallets in environments with high moisture levels or harsh conditions, such as outdoor storage or humid climates.

Pressure treatment is a reliable option for logistics managers who require pallets that can withstand the elements. These pallets can resist rot and insects, maintaining longevity in the toughest conditions. However, because pressure-treated wood contains chemicals, businesses must follow safety guidelines when handling or disposing of it.

Fumigation

Fumigation is another way to comply with international regulations, particularly when shipping pallets across borders. It involves using chemicals, such as methyl bromide, to kill pests living in the wood. While effective, fumigation is less environmentally friendly than other treatments due to the chemicals involved.

You must mark fumigated pallets with a stamp indicating that the treatment took place, like heat-treated pallets. Logistics managers should understand the potential health and environmental risks of fumigation. Still, it may be the only option to meet export requirements for certain countries.

Chemical Treatment for Fire Resistance

Manufacturers can apply fire-retardant chemicals to wood via pressure treatment. This process slows down combustion and can prevent or minimize fire from spreading. Businesses with an elevated fire risk can enjoy peace of mind knowing that appropriate safety measures are in place.

Warehouses or storage facilities that handle flammable materials generally use fire-resistant pallets. While not every industry requires this treatment, it’s a valuable investment for companies looking to enhance safety protocols.

Bio-Treatment

Bio-treatment methods for wooden pallets have gained popularity as sustainability becomes increasingly important in business. Bio-treatment involves using organic materials to treat wood, such as plant-based oils or naturally occurring fungi that repel insects and pests. This method appeals to eco-conscious businesses looking for alternatives to chemical treatments.

Bio-treated pallets offer many of the same benefits as traditional treatments, including pest resistance and durability, without the environmental impact. Choosing new wood pallets treated with bio-friendly options is a step toward greener logistics for companies aiming to reduce their carbon footprint.

Water Repellent Treatment

Water repellent treatments prevent moisture from penetrating wood. This process benefits pallets stored in damp environments or exposed to rain. The treatment involves applying a water-resistant coating to the wood, protecting the pallet from swelling, warping, or developing mold.

This treatment is ideal for businesses operating in regions with high humidity or rainy seasons. Water-repellent pallets maintain their structural integrity longer and protect the goods stored on them from moisture damage. Businesses investing in long-lasting pallets should consider this option when reviewing their logistics management.

Heat-Chemical Combination Treatments

Some wooden pallets undergo a combination of heat and chemical treatments to offer maximum protection. These pallets are pest-free, fire-resistant, and resistant to rot and decay. Businesses can ensure that their pallets will hold up under extreme conditions by combining multiple treatment methods, whether exposure to pests, fire hazards, or moisture.

Combination treatments are more expensive, but they offer unparalleled durability and protection. This treatment option can prove worthwhile for industries that rely on heavy-duty logistics operations, such as manufacturing or construction.

Recycled Pallets and Their Treatment Needs

Recycled pallets have become popular for businesses looking to reduce waste and cut costs. However, recycled pallets often need additional treatment, especially when repurposed for new uses or international shipping. Logistics managers should know the treatment history of recycled pallets to ensure they meet industry standards.

For example, you may need to heat treat or fumigate your recycled pallets to comply with current regulations. While recycled pallets can save money and are great for the environment, understanding their treatment needs is essential to maintaining a safe and compliant supply chain.

The Importance of Choosing the Right Treatment

The appropriate treatment for your wooden pallets depends on your business needs, industry regulations, and warehouse environment. Understanding the types of treatments available is crucial, whether you’re shipping internationally, storing pallets outdoors, or seeking eco-friendly solutions.

Heat treatment or fumigation can prove worthwhile for businesses that frequently deal with pests. Pressure or water-repellent treatments can extend your pallets’ lifespan if it faces exposure to the elements. Bio-treatment and recycled pallets provide green alternatives for companies focused on sustainability.

First Alliance Logistics Management: An In-Demand Pallet Supply Company

Consider these types of treatments used on wooden pallets, as each has its own benefits and use cases. Businesses can choose the right method based on their needs, compliance requirements, and sustainability goals.

Understanding these treatment processes can help you make smarter decisions that benefit your operations, whether investing in recycled or wood pallets. Contact First Alliance Logistics Management today to discuss ordering custom pallets from an in-demand pallet supply company.

Our new wood pallets are durable and safe and will comply with the appropriate regulations for your industry and shipping concerns. Visit our website for more information about our services.