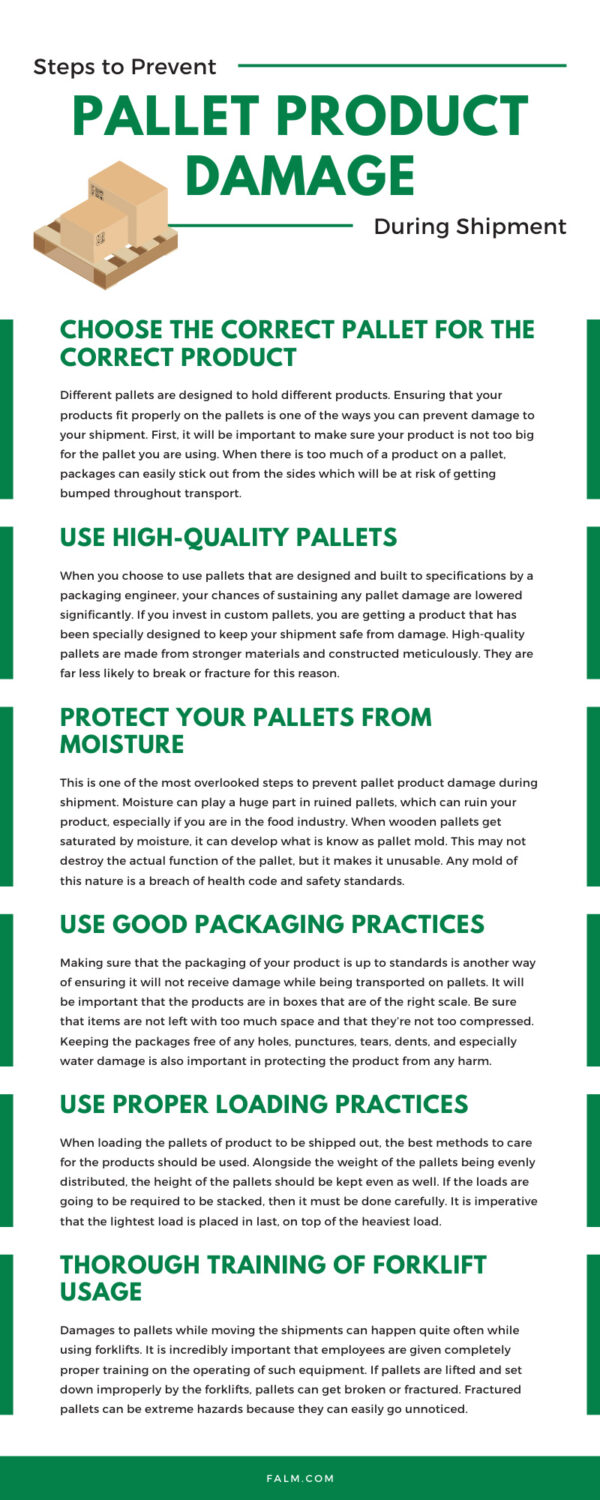

It is extremely important for companies to consider ways that they could prevent pallet product damage. Ensuring that your company can avoid situations of damage to pallets, crates, and packages is a key component in managing your supply chain. The worst thing you can face from pallet damage is not the look of a broken pallet, but the potential damage to your product that is being shipped. After all, the pallets are what hold the multiple packages during transport, ensuring that they stay in place in a safe, practical way. Having products potentially ruined by damaged pallets can present potential questions about your company’s reliability to your customer. If there is failure to prevent damage to your pallets, it can not only result in lost product, but it could also put your customer at risk of injury. Risks of pallets being damaged can come from many different sources, which can make it seem stressful to look for them. Luckily, there are many things you can do to prevent any of this damage. Here we will discuss different steps to prevent pallet product damage during shipment.

Choose the Correct Pallet for the Correct Product

Different pallets are designed to hold different products. Ensuring that your products fit properly on the pallets is one of the ways you can prevent damage to your shipment. First, it will be important to make sure your product is not too big for the pallet you are using. When there is too much of a product on a pallet, packages can easily stick out from the sides which will be at risk of getting bumped throughout transport. This can also lead to the pallet breaking at the joints, as the load will likely be too heavy.

You also don’t want the pallet to be too big for your product. This can lead to an improper load balance which can cause things to fall. Also, the pallets will be designed to handle a certain weight. If the pallets have a 1,000-pound limit and you go over that, there will likely be damage to the pallet and product. Make sure to stick to the right amount of weight, as well as the proper distribution, to avoid damage to your products. Lastly, if you intend on using any strapping or banding to secure the product on the pallet, it will be important to make sure the packages are flush on it. If there’s too much space around the product, the deck boards can take the brunt of the tightening, which could make them break.

Use High-Quality Pallets

When you choose to use pallets that are designed and built to specifications by a packaging engineer, your chances of sustaining any pallet damage are lowered significantly. If you invest in custom pallets, you are getting a product that has been specially designed to keep your shipment safe from damage. High-quality pallets are made from stronger materials and constructed meticulously. They are far less likely to break or fracture for this reason. If you have chosen customized pallets, there are different ways you can have the pallets designed. Through a pallet distribution company, they can be constructed in all different sizes and shapes. Your pallets can be designed to fit shipment trucks, as well as storage spaces, further protecting any accidents.

Protect Your Pallets from Moisture

This is one of the most overlooked steps to prevent pallet product damage during shipment. Moisture can play a huge part in ruined pallets, which can ruin your product, especially if you are in the food industry. When wooden pallets get saturated by moisture, it can develop what is know as pallet mold. This may not destroy the actual function of the pallet, but it makes it unusable. Any mold of this nature is a breach of health code and safety standards. If these are used on products for the pharmaceutical or food markets, then the products will likely have to be thrown out upon arrival.

Use Good Packaging Practices

Making sure that the packaging of your product is up to standards is another way of ensuring it will not receive damage while being transported on pallets. It will be important that the products are in boxes that are of the right scale. Be sure that items are not left with too much space and that they’re not too compressed. There will likely need to be proper packing materials in each box that will protect the product from any excessive movement or impacts. Keeping the packages free of any holes, punctures, tears, dents, and especially water damage is also important in protecting the product from any harm. One other practice that can help in avoiding damages is using spill-resistant tape that will seal the packages. This will prevent any liquids, like water, from potentially getting inside.

Use Proper Loading Practices

When loading the pallets of product to be shipped out, the best methods to care for the products should be used. Alongside the weight of the pallets being evenly distributed, the height of the pallets should be kept even as well. If the loads are going to be required to be stacked, then it must be done carefully. It is imperative that the lightest load is placed in last, on top of the heaviest load. It will help to avoid any double stacking of pallets. Also, be sure to use cushioning in gaps between the different loads. This further helps avoid any product damage that could possibly happen during the transporting process.

Thorough Training of Forklift Usage

Damages to pallets while moving the shipments can happen quite often while using forklifts. It is incredibly important that employees are given completely proper training on the operating of such equipment. If pallets are lifted and set down improperly by the forklifts, pallets can get broken or fractured. Fractured pallets can be extreme hazards because they can easily go unnoticed. Pallets with fractures can end being used, which can break further while carrying heavy amounts of product. Knowing how to operate forklifts properly will further protect pallets, lessening the likelihood of packages falling and getting crushed.