One of the largest growing trends in the pallet industry is the use of recycled wooden pallets. In fact, over a thousand US pallet companies recycle pallets. Recycled pallets have gained popularity for a variety of reasons. With sustainability at the forefront of many supplier models and the increasing costs of lumber, many businesses are using recycled wooden pallets.

However, these pallets undergo a much more complex system than the standard reduce and reuse recycling chain. In fact, recycled wooden pallets serve a vital purpose in the supply chain and are an integral part of the pallet industry. So, where do recycled pallets and their materials come from? To learn more, keep reading.

From New Pallets To Reused: Following the Pallet Supply Chain

Once pallets have been entirely constructed with virgin materials and automated machinery, they are sold and used for businesses to store and ship merchandise. However, once these new pallets are created and used by enterprises, their movement in the supply chain does not stop.

Businesses constantly push inventory to empty pallets and move these materials to make room for more pallets with new products. Once a pallet is no longer new, they are given grades by buyers and bought by businesses that repair them for their storage. As recycled pallets are worn and used over time, companies will continue to buy, redesign, reuse, and move these pallets through the supply chain.

It’s important to note that creating new pallets is vital to feeding a constant flow of recycled pallets into this supply chain cycle. When pallets are reused until they are no longer recyclable, manufacturers must supply new pallets to replace them and continue this reuse model.

Where Do Recycled Pallets Come From?

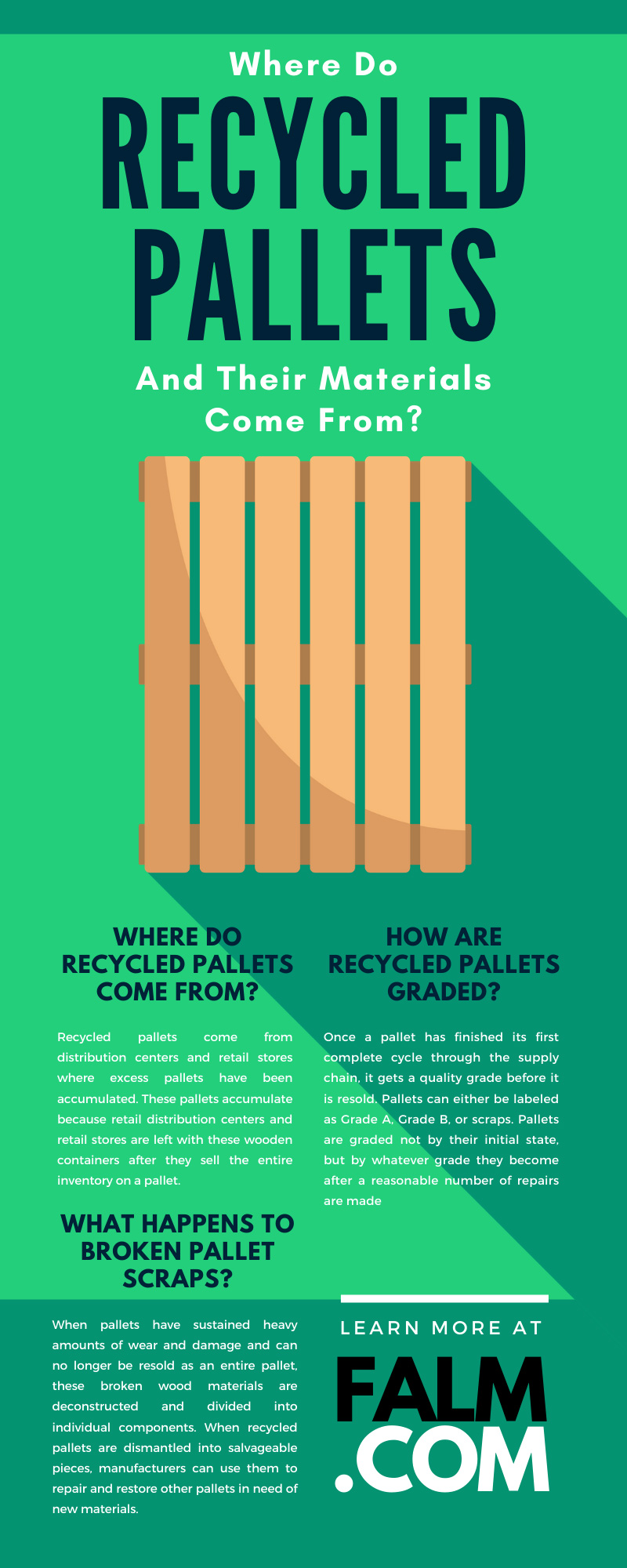

Recycled pallets come from distribution centers and retail stores where excess pallets have been accumulated. These pallets accumulate because retail distribution centers and retail stores are left with these wooden containers after they sell the entire inventory on a pallet.

Piles and piles of broken pallets sit in these distribution centers across the country. If these materials were thrown away or sent to landfills on a daily basis, they would broadly cover the majority of US landfills. For this reason, most states have laws against discarding pallets in landfills.

However, waste is easily avoidable because recycling these pallet parts is convenient. Businesses can contact a pallet removal company to clear distribution centers of these broken pallets and restore their materials for reuse. When businesses avoid creating this massive amount of waste and instead send these broken pallets down the supply chain for reuse, they significantly reduce their carbon footprint. They can also generate revenue by selling broken pallets.

How Are Recycled Pallets Graded?

Once a pallet has finished its first complete cycle through the supply chain, it gets a quality grade before it is resold. Pallets can either be labeled as Grade A, Grade B, or scraps. Pallets are graded not by their initial state, but by whatever grade they become after a reasonable number of repairs are made.

The number of feasible reuses for recycled pallets varies based on circumstance. The roughness of materials and the handling environment of recycled pallets contribute largely to their wear and damage over time. Depending on these factors, pallets can easily sustain or drop in quality grade

Size can also factor into the recyclability of a pallet. The standard dimensions of the majority of pallets are 48×40. These pallet sizes are more likely to be bought and reused often by businesses frequently. However, pallets with more customized designs and specified measurements are more likely to be less recyclable. Since customized sizing is less likely to be used by businesses, these pallets are often dismantled and repurposed after one or two uses.

What Happens To Broken Pallet Scraps?

So, what happens to pallets that are graded as scraps? When pallets have sustained heavy amounts of wear and damage and can no longer be resold as an entire pallet, these broken wood materials are deconstructed and divided into individual components.

When recycled pallets are dismantled into salvageable pieces, manufacturers can use them to repair and restore other pallets in need of new materials.

If broken pallets are considered unsalvageable and cannot be used to repair other pallets, these materials are ground into mulch. If businesses did not grind worn wooden materials into mulch, wood waste from these materials would be highly excessive. These repurposed mulch products can then be used as a revenue stream for businesses to offset transportation and handling costs.

Recycled pallets are a vital part of the pallet industry system. While restoring these pallets is a labor-intensive endeavor, the reuse of these materials helps keep inventories moving and drastically reduces overall waste.

Without recycled pallets, new pallets could be more costly to make upfront. These pallets would create extensive products of waste and sit uselessly in landfills. Instead, businesses have created a balanced system to create new pallets, reuse these materials, repurpose scraps, and feed in new pallets to renew this cycle. With these systems all working together, the pallet supply chain never stops moving and goods can consistently be shipped and sold.

When businesses understand where recycled pallets and their materials come from, they can better visualize how these pallets factor into the larger industry supply chain. When they have an excess of pallets leftover from their retail and distribution centers, they have a better understanding of how vital pallet removal companies are to moving these materials and reusing these containers.

Here at First Alliance Logistics Management, we offer pallet resourcing and have industry expertise and experience in the building, recycling, and managing different types of pallets.

Whether you want to learn more about recycled buyback programs, the pallet supply chain, or any other information on the use of pallets for your business, our expert team will assist all your pallet needs. To learn more about how we can service your company or browse more of our blogs on the use of pallets in different industries, check out our website.